Engineering Products for Better Value

Last few weeks have not been kind on the industry. The recent pandemic and the economic slump that followed it has made leaders across the industry search for innovative cost optimization measures to offset pressure on revenues and margins. However lessons from the past show that using the challenging times to drive sustainable cost transformation programs yielded clearly higher returns than pure, short term focused cost cutting. Value Engineering, the multi-dimensional creative effort to achieve essential product functions at the lowest total costs is becoming the most adopted cost optimization technique among forward looking companies.

However, it is important that cost saving initiatives result in real transformation than becoming counter-productive.

This virtual session conducted by L&T technology Service, in association with Danaher talks about the best practices one should follow to make the best of the situation & discuss about the power of collaboration.

Fill the form to access the recording of the session.

Key Takeaways

- Program based execution with an Onsite Offshore model for a long-term engagement is an optimal approach to achieving the targets with resource flexibility

- Explore innovative business models to overcome some of the challenges in making progress on VAVE ideas. A good example - gain sharing model

- Reliability and Process Improvement are also key areas of a VAVE program contributing to the cost savings alongside the core product changes as illustrated by the Immunoassay project VAVE with savings of over 1mn/Year.

- Concurrent VAVE, Packaging, eIFU & Labelling are areas that can be harnessed to bring in better value to products even during their development as also a part of the sustenance activities.

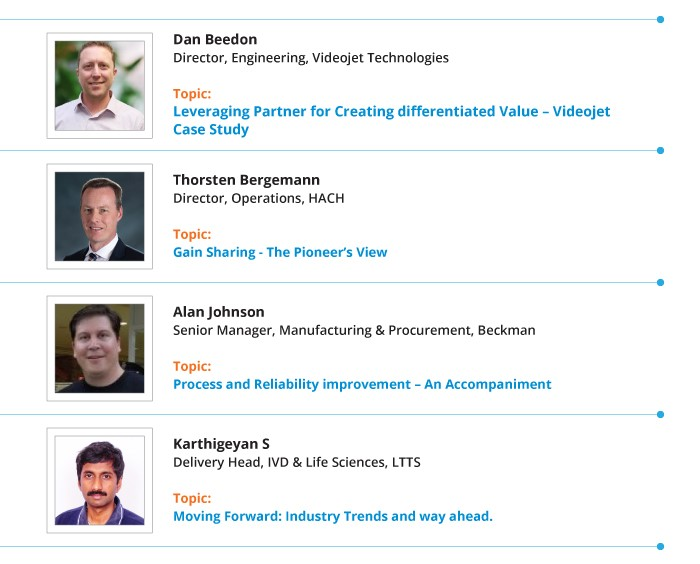

Speakers