Challenges Daunting the CPG Industry

CPG manufacturers are producing either commodity products driven by volume or luxury products at the other end, driven by margin. For both the categories, effective new product development, building supply chain effectiveness and cost control measures can help businesses improve their margin and maintain their cost-effectiveness. The current times have pushed companies to adopt and scale digital to build resilience and achieve operational efficiency. There has never been a greater impetus for integrating digital and physical systems to optimize and transform the existing factories into future-ready factories.

Digital as a Means to Enable Transformation

While each organization’s digital goals will be unique to their strategy and vision, understanding where they stand would enable businesses to define the digital roadmap effectively. Assessment of current digital maturity can help organizations to identify the gaps in their digital journey, benchmark against their industry peers and create an action plan with short-term and long-term objectives to achieve their business objectives.

One digital thread. One Mission.

Key KPIs

- Explore New Business Model: Digital technologies to adapt evolving market dynamics with changing customer expectations and external factors to achieve sustainable growth.

- Total Cost of Ownership: Digital investment, operating expenses And contribution margin by leveraging the existing infrastructure

- Business Sustainability: Identify the business process to prioritize the digital initiatives

Key KPIs

- Productivity: See that the plant is performing as per average throughput on a daily basis

- Downtime: Monitor the downtime due to production changeover, emergency shutdown to maintain the productivity of the floor

- Safety: Prevent workplace incidents/accidents

- Overall Equipment Effectiveness (OEE): OEE helps about the overall performance of the factory

- Quality: Ensure non-compliance in production is kept to the minimum

Key KPIs

- New Product Development (NPD): Accelerate the NPD process to meet changing market demands

- Utility Monitoring: Optimized usage of key utilities like water, air, gas, electricity, steam

- Quality: Ensure quality in Product and Process

- Project Progress Performance: Track how well the project is progressing as per its plan

- Asset Reliability: Ensure minimum unplanned breakdown so that plant assets perform to their optimum level

Focus Areas

Continual Transformation (Ctr)

Cluster Areas

- Consulting Services

- Predictive Analytics & Decision Support Services

- Robotization Services

Benefits Delivered

- Expert know-how, step-by-step implementation

- Maximize plant availability, early fault detection

- Improved working condition, operator enablement

Connected Value Chain (CVC)

Cluster Areas

- Design & Manufacturing Engineering Services

- Digital Threading & Twinning Services

- Knowledge Threading & Management Service

Benefits Delivered

- Shorter time to market, extended life-cycle

- Easy access to product data, tailored learning

- Next level productivity, engaged participation

Digital Assets & Security (DAS)

Cluster Areas

- Asset Reliability Services

- Digitization & Data Centricity Services

- IT-OT Integration & OT Security Services

Benefits Delivered

- Early fault detection, prolonged service life

- Step-by-step digitalization, data driven analysis

- Expert vulnerability and risk analysis

Intelligent Sustenance (INS)

Cluster Areas

- Genealogy & Tracking Services

- Migration & Support Services

- Sustainability Services

Benefits Delivered

- Improved quality, compliance monitoring

- Application enhancement, time & cost optimization

- Sustainable manufacturing, optimized energy cost

Smart Manufacturing & Operations (SMO)

Cluster Areas

- Automation Services

- Operations Improvement Services

- Visibility & Dashboarding Services

Benefits Delivered

- Optimum people & equipment usage, improved OEE

- Fast trouble shooting, inventory optimization

- End-to-end visibility & decision insights

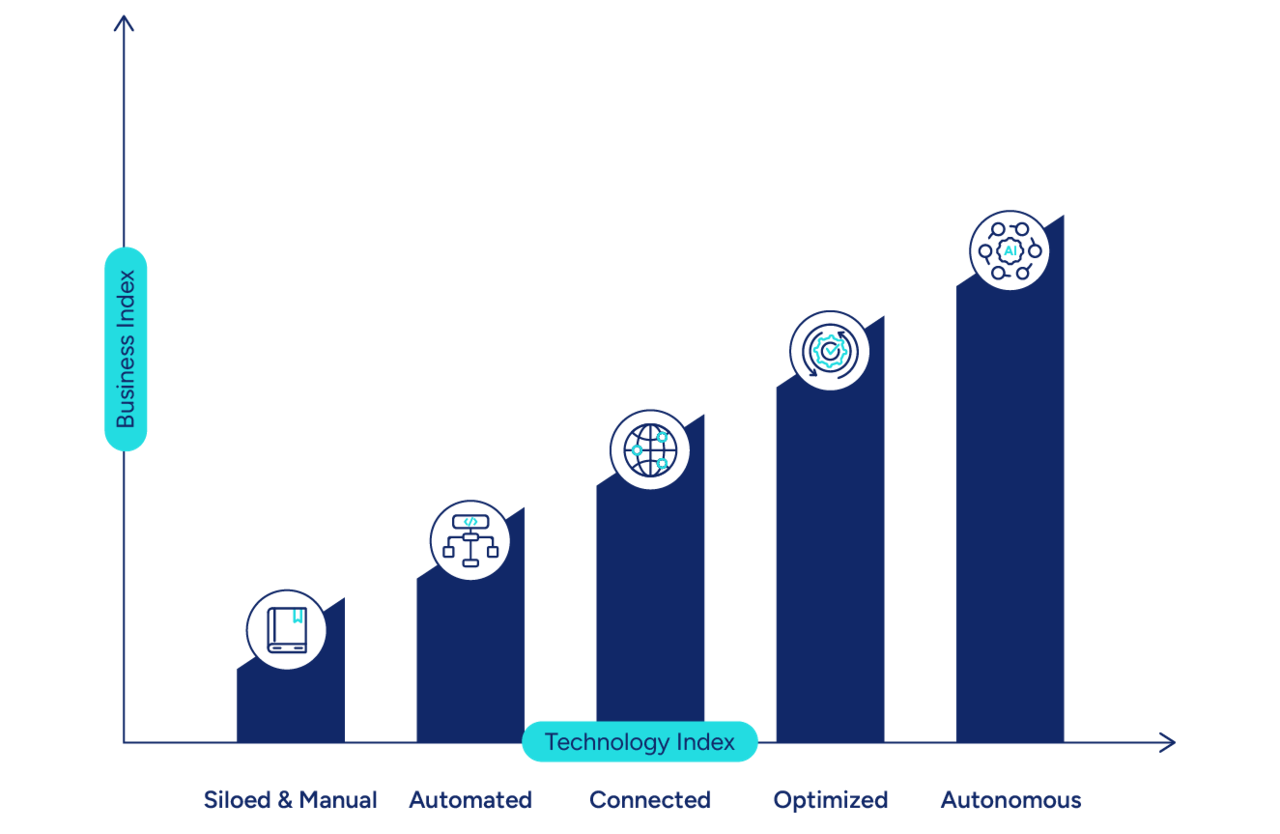

Assess Your Digital Maturity

Scale Your Digital Maturity

Journey

Designed to improve plant health, ARC is a one-stop solution to overcome unplanned downtime and undetected quality issues. It can help you simplify engineering, monitoring, discovery, and prediction across various manufacturing operations. With real-time condition monitoring and reliability predictions, ARC ultimately minimizes unscheduled outages, increases utilization, and augments productivity without fail.

Benefits:

- >25% reduction in reactive maintenance

- 2% - 5% improvement in overall yield

Energy and Sustainability Manager’s comprehensive plant asset modeling puts compliance at the center stage. The solution helps you in forecasting energy need, track consumption & KPIs, and compare performances to deliver on your goals. Through an integrated, compliance-driven approach, Energy and Sustainability Manager will help you accomplish energy cost savings of up to 10-15%.

Benefits:

- Boosted operational efficiency

- Ensured real-time monitoring of production