Artificial Intelligence is no longer a frontier, but rather, a transformative force reshaping the global aerospace engineering landscape. From next-gen combat systems to minimal-downtime aircraft fleets – with intelligence becoming the backbone of every mission, platform, and decision – AI is powering predictive logistics, accelerating mission readiness, and enabling next-gen autonomy across every layer of the value chain.

And yet, despite sustained breakthroughs, from predictive maintenance, satellite analytics, to autonomous swarming, a key question persists: How do we move beyond the PoC trap and scale AI meaningfully, responsibly, and securely in one of the world’s most complex, safety-critical domains?

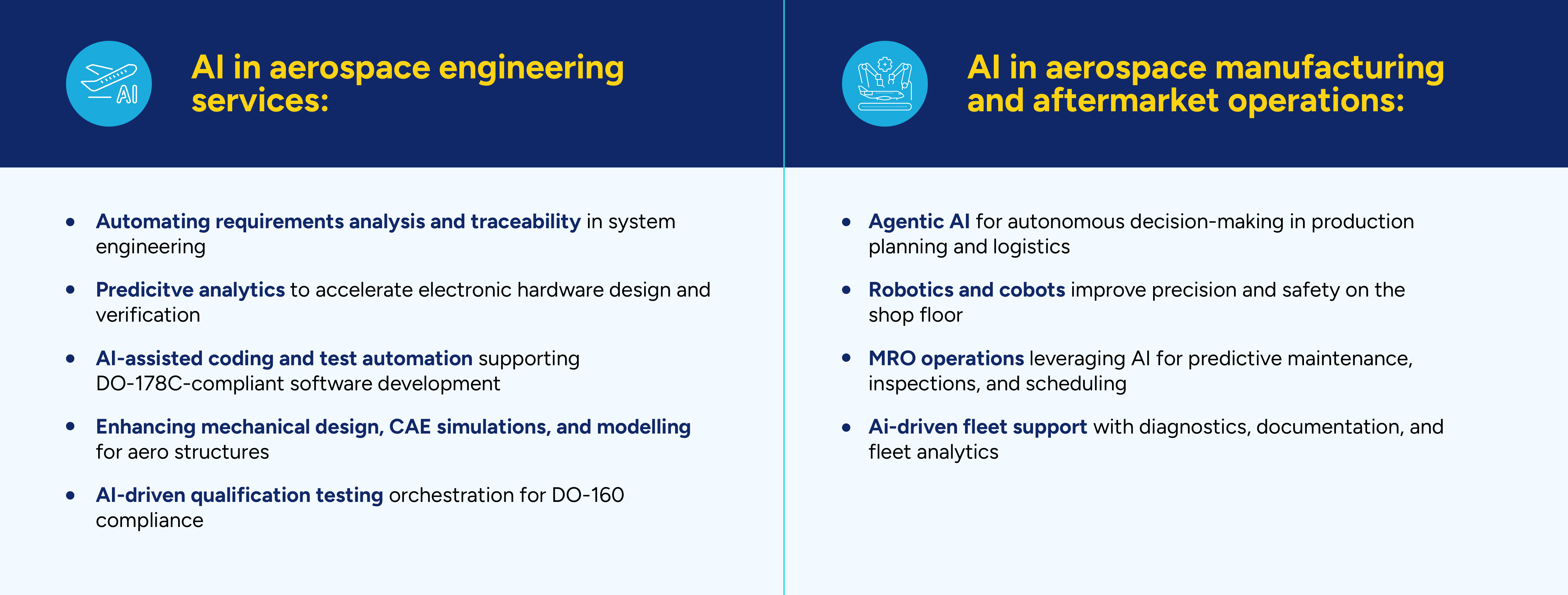

Current Landscape: AI in Aerospace Engineering

While AI adoption in aerospace engineering is advancing, it is still largely in isolated PoCs. These initiatives demonstrate technical feasibility and early ROI, but often stall before reaching enterprise-wide deployment.

Consequently, most organizations continue to struggle in their efforts to scale AI-enabled innovations across geographies and platforms.

Challenges in Scaling AI in Aerospace Engineering

The challenges in scaling AI in aerospace engineering can be seen across:

Certification and Compliance Complexity

The aerospace industry operates under strict regulatory frameworks requiring determinism, traceability, and verifiability – qualities not natively inherent to most AI systems. This includes:

- Software: DO-178C compliance challenges while leveraging opaque deep learning models

- Hardware/FPGA: DO-254 mandated exhaustive validation for reliability

- Mechanical and Environmental Testing: DO-160 requires AI not to compromise EMI/EMC, vibration, or thermal tests

- System Standards: ARP4754A and ARP4761 demand rigorous safety assessments and functional hazard analysis

Mismatch Between Technical and Business Teams

Another persistent scaling challenge is the disconnect between engineering teams developing AI solutions and business teams driving strategic decisions, evident across:

- Different Priorities: Technical teams focus on models, pipelines, and compliance, while business teams prioritize ROI and operational timelines

- Leadership gaps: Scaling AI demands leaders who bridge technical capability and enterprise value

- Change Management Resistance: Scaling often requires workflow and process changes, which can face organizational pushbacks. Without buy-in from both engineering and business stakeholders, scaling efforts can face internal resistance

Integration with Legacy Systems and Infrastructure

Several aerospace organizations still operate on legacy systems that were never designed for AI-driven workflows, resulting in

- Data Silos and Incompatibility: With engineering data remaining fragmented across tools, formats, and departments. AI systems require unified, high-quality datasets – something legacy environments rarely support

- Toolchain Integration: Where AI models need to interoperate with CAD, PLM, ERP, and simulation environments

- Security and IT Constraints: Including stringent cybersecurity measures that can limit AI deployment at scale

- Cultural Resistance: Where the established teams may resist AI integration that disrupts familiar processes

Strategic Enablers for Scaling AI in Aerospace Engineering

Scaling AI in aerospace requires a deliberate, multi-dimensional strategy – focusing on compliance, integration, collaboration, and infrastructure. This calls for a three-phase approach, involving:

Designing for Safety, Determinism, and Compliance

- Explainable AI models where transparency is critical

- AI Assurance Frameworks aligned with DO-178C, DO-254, DO-160, and ARP4754A

- Digital twins and Simulation to validate under realistic conditions

- Safety Cases for AI: Justify AI integration with evidence from testing and operational data

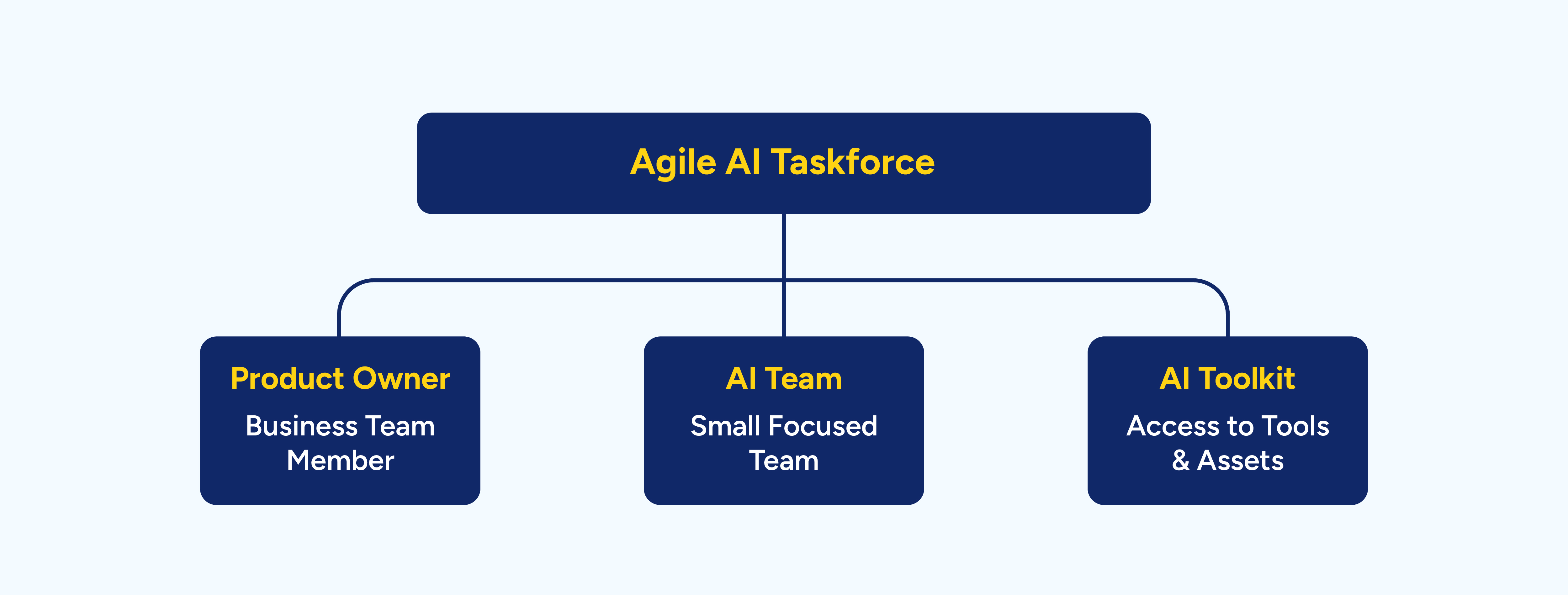

Bridging the Gap Between Technical and Business Teams

- Agile AI Delivery Model using MVPs to quickly validate feasibility

- Cross-Functional Agile Teams: Form AI Taskforces comprising:

- A business team member as Product Owner to define value, priorities, and success metrics

- A small, focused AI team with access to an internal AI Toolkit – including data connectors, model templates, and deployment pipelines

- Reusable AI Assets: Encourage the creation of reusable components – pre-trained models, feature libraries, validation scripts – that can accelerate future use cases and reduce duplication

Organizational Culture Shift: Promote a culture of experimentation, transparency, and collaboration, and recognize that AI adoption is not just a technical shift, but rather, a mindset changes across engineering and business functions

Modernizing Data and System Infrastructure

- Unified Data Platforms consolidating engineering, manufacturing, and service data across tools and formats

- Toolchain Interoperability with APIs or low-code platforms bridging existing systems

- Edge & Cloud Deployment Models: Balance scalable cloud processing with latency-sensitive edge AI

- Cybersecurity & Governance safeguarding compliance and data integrity

Case Examples and Emerging Patterns in Scaling AI

While many aerospace players are still navigating early AI adoption, a few are demonstrating scalable, repeatable patterns, across:

- Engineering: AI-Augmented Qualification Testing

An aerospace engineering team used AI-driven orchestration for DO-160 testing, reducing cycle time by 30% while maintaining compliance – enabled by an agile MVP approach - Manufacturing: Cobots and Agentic AI in Assembly Lines

AI-guided cobots improved precision, reduced human error, and scaled across multiple facilities using reusable modules and centralized data platforms - Customer Services: AI-Powered Fleet Diagnostics

A fleet services provider used AI to analyze telemetry and maintenance logs, predicting failures and enabling proactive interventions

Looking Ahead: The Next Frontier of AI in Aerospace Engineering

As AI moves beyond pilots and prototypes, its potential lies in becoming a core enabler of intelligent engineering, resilient manufacturing, and proactive customer support. The next wave of innovation will be shaped by deeper integration, smarter automation, and more adaptive systems. We feel that this would result in:

More AI-Native Engineering Workflows

Engineering tools will evolve to become AI-native – embedding intelligence directly into design, simulation, and verification environments. Including:

- Generative Design optimizing aero structures and electronics

- Autonomous Verification continuously validating designs against compliance standards like DO-178C, DO-254, and DO-160, reducing manual effort and accelerating certification

- Digital Threads and Twins spanning the lifecycle for predictive insights and feedback loops

Hyper-Automated Manufacturing and MRO

Manufacturing and aftermarket operations will become increasingly autonomous and adaptive, with:

- Agentic AI in Production orchestrating workflows, managing resources, and responding to disruptions in real time

- Context Aware Cobots collaborating dynamically with operators

- Predictive and Prescriptive MRO: AI will not only predict failures but also prescribe optimal maintenance actions, reducing cost and downtime

AI-Driven Customer Experience

Customer support will shift from reactive to proactive, powered by intelligent systems, across:

- Self-Healing Aircraft Systems that would leverage onboard AI to detect, diagnose, and even resolve issues autonomously

- Conversational AI to empower Tech Support teams troubleshoot issues leveraging natural language interfaces

- Fleet Intelligence Platforms that would use AI to monitor, analyze, and optimize fleet performance across geographies and operators

Governance, Ethics, and Human-AI Collaboration

As AI becomes more embedded, organizations must invest in responsible AI practices.

- AI Governance Frameworks for model validation, ethical boundaries, and data usage

- Human-in-the-Loop Systems where AI augments but does not replace human expertise and decision-making

- Continuous Learning models evolving with new data, regulations, and operational feedback, requiring ongoing oversight and refinement

From Algorithm to Altitude – It is Time to Industrialize AI in Aerospace Engineering

AI offers significant transformative potential for aerospace engineering. However, realizing this at scale requires more than technical experimentation – it calls for a strategic, structured, and safety-conscious approach that aligns with the industry's high standards for compliance, reliability, and performance.

As the aerospace industry evolves, those who succeed in scaling AI will be the ones who:

- Treat AI as a core engineering capability, not a side experiment

- Build agile, cross-functional teams that bridge business and technical domains

- Invest in compliance-aware AI frameworks that meet the demands of DO-178C, DO-254, DO-160, and ARP4754A

- Create reusable AI assets and toolkits that accelerate innovation across programs

Our global teams continue engineering the key infrastructure that is helping make AI real, repeatable, and responsible across the aerospace lifecycle. And as current trends continue to strengthen, it is evident that the future will not be defined by the one who has the most AI PoCs, but rather, by those who can deploy AI with purpose, scale it with rigor, and sustain it with confidence.

Because, after all, AI adoption is not just a technical milestone. It is a strategic engineering responsibility, a leadership choice, and a promise to engineer intelligence that endures – safe, secure, and at scale.