Rail transportation ranks high among one of the most economical and low carbon footprint modes of moving goods and passengers. The segment continues to evolve rapidly, driven by accelerating technology advances, growing demographic shifts, and a rising focus on sustainability.

Digitalization and the adoption of AI & Digital Services are increasingly playing major role in ensuring the safety, reliability, and efficiency of rail networks worldwide.

While the initial investment on railroad tracks can be high, there is also a need for periodic maintenance to avoid potential accidents from the wear and tear of the tracks. Freight trains, with a high per axle load can lead to faster wear out, call for more frequent inspections.

With the rise in the demand for more loading capacity and higher operating speeds – key factors that affect rail-track health – legacy approaches to track inspection can become a bottleneck. Combining compute vision-based detection techniques, along with data science backed methodologies, opens up new possibilities to detect and predict track defects, driving a safer rail transport system.

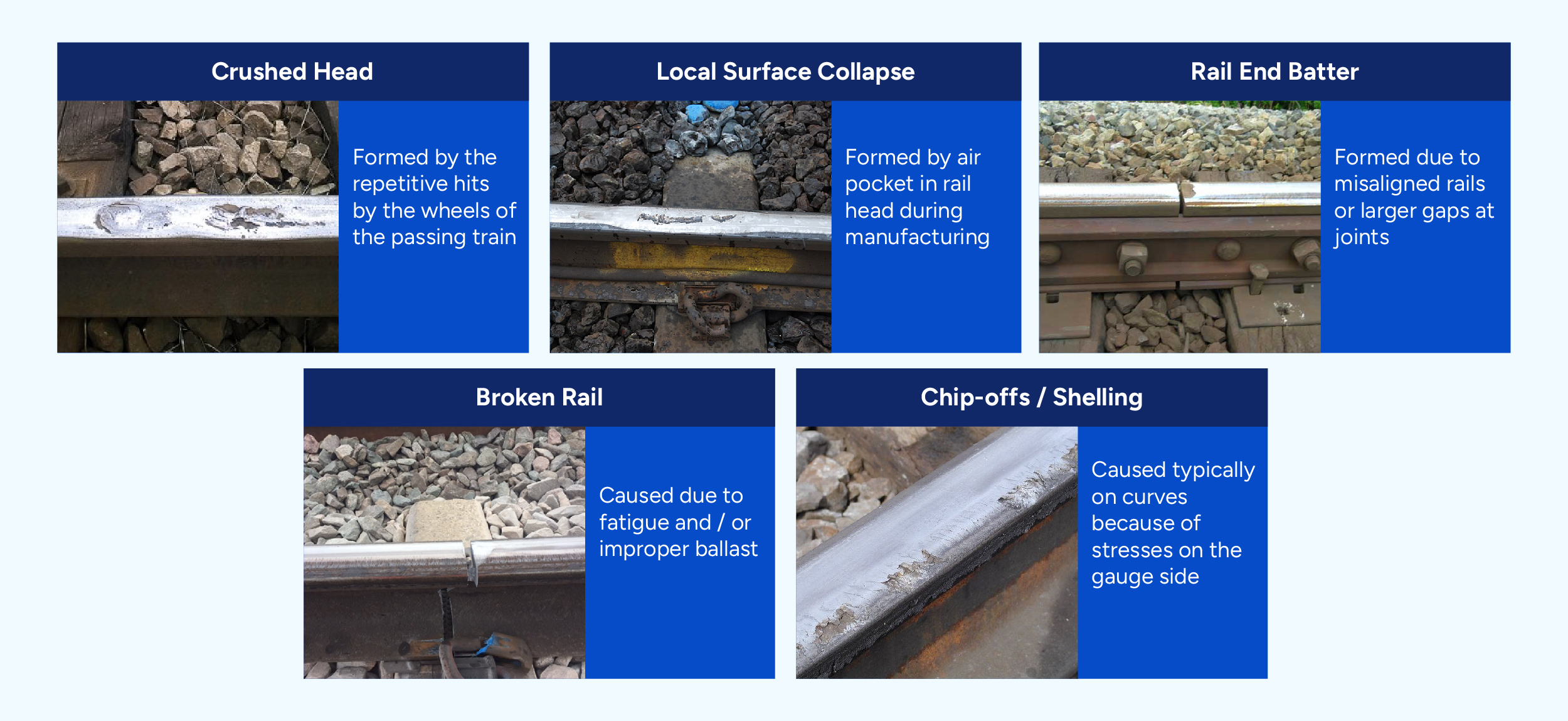

Rail Track Defects and redressal

A railroad undergoes different kinds of wear and tear. This includes:

Worldwide, different railroad operators, based on their specific conditions, have come to adopt different methods of inspection. The most widely used is the manual inspection, where a trained professional inspects around five to six km per day.

A few railroads have started shifting to the use of trolleys for their manual track inspections. Typically, these compact vehicles, driven by a small gas engine, can provide speeds up to 25 kmph. Once a defect is identified, the inspector documents the fault and the nearest milepost with other relevant information in their logbook. The data collected is then passed on to the maintenance engineer in-charge of that section for scheduling the repairs.

Scheduling is prioritized based on the severity of the defect.

The need for manual data transfer and scheduling, however, increases the time to repair and raises the risk of a derailment. With manual inspection, the length of track covered per day is also considerably minimal, while increasing costs and the raising probability of a defect going unidentified.

However, automating railway track fault identification can continue to pose a challenge. Defects such as crushed heads also need depth of the deformation to be identified. In desert areas, there is a further requirement to measure the height of sand deposition, whereas some defects like broken rails and defective rail joints can only be detected with compute vision methods.

LTTS’ TrackEi™ Solution

TrackEi™ from L&T Technology Services (LTTS) is built on modular blocks and can be integrated to have different models based on the end client requirements. The solution has two main vision sensors; a high-speed machine vision camera and a 2D Laser profiler.

Developed on the NVIDIA Jetson Platform, TrackEi™ runs light-weight models for enhanced real-time detection performance. The machine vision camera captures camera images of the surface defects on the rail track at rates ranging between 0 to 50 fps. The capture fps is based on the travel speed and the FOV width. All the incoming images after pre-processing are passed through LTTS patented (applied) algorithm and pre-trained model for defect detection.

When the laser profiler is available, TrackEi™ also keeps collecting the laser imagery data. This, however, is only processed if the compute vision-based system triggers a defect detection, ensuring the optimum utilization of the CPU/GPU power.

In case a defect is found. the image and the 2D laser profiles along with the speed, location tag and other relevant information is saved as a report file. With access to a data network, the report file is transmitted to the cloud platform. The cloud app also triggers notifications to the registered personnel to take the necessary actions after investigating the defect severity.

Future-Ready with Model Training

The TrackEi™ comes with a built-in capture mode. With this mode enabled, the solution takes images and saves them to its internal storage. The data engineers collect these recorded images and perform data cleaning and labeling. The models are trained using workstations with NVIDIA GPU cards like Quadro P2000, A2000 and RTX3060. Robust research has delivered an optimum model that yields best possible accuracy, precision, and recall rates.

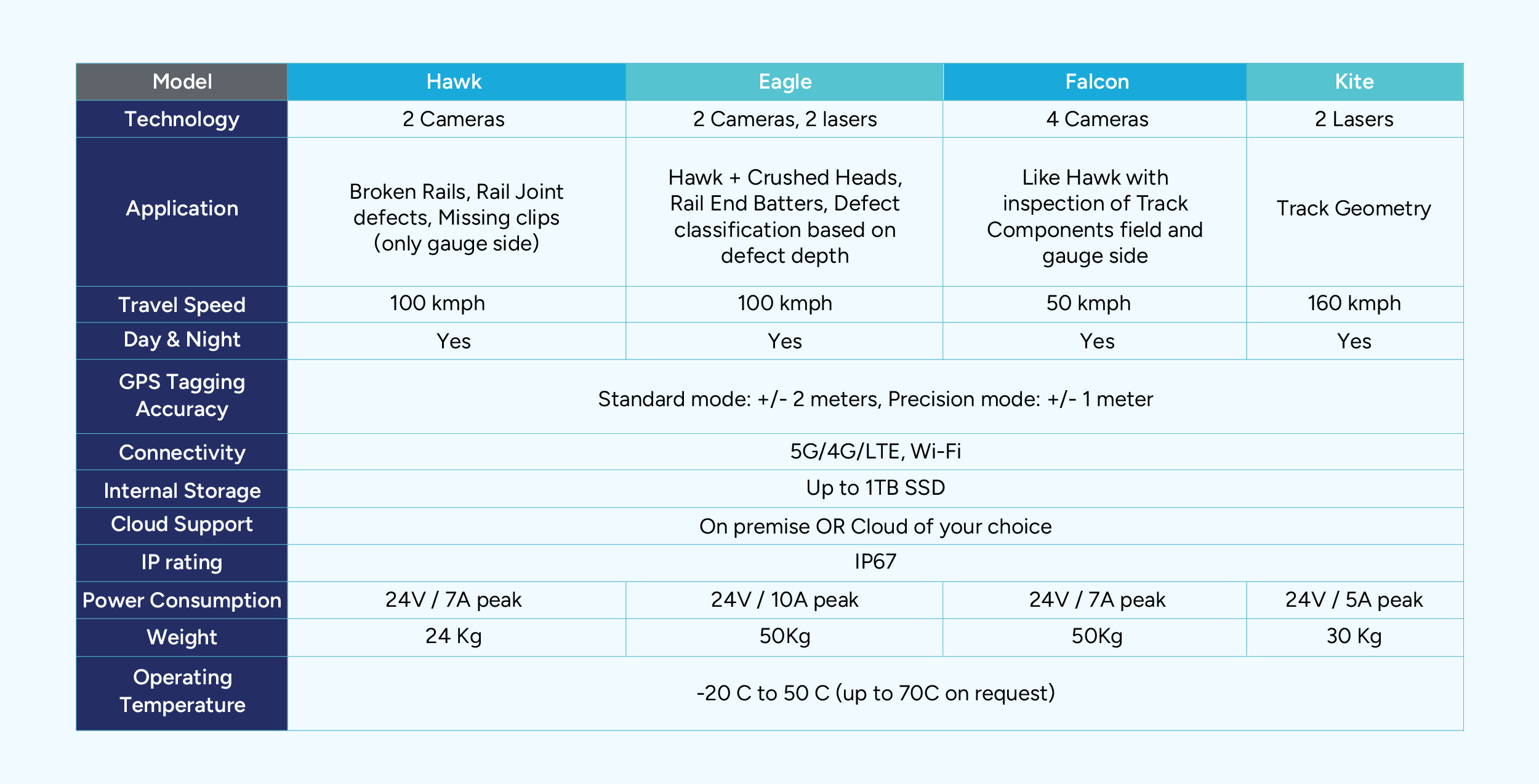

High-level specifications of the TrackEiTM models are shared below:

NVIDIA’s GPUs play a crucial role in enabling the LTTS TrackEiTM's advanced capabilities. By accelerating image processing, training, and analysis, these GPUs help ensure the timely detection and mitigation of rail track defects, contributing to safer and more reliable railway operations worldwide.