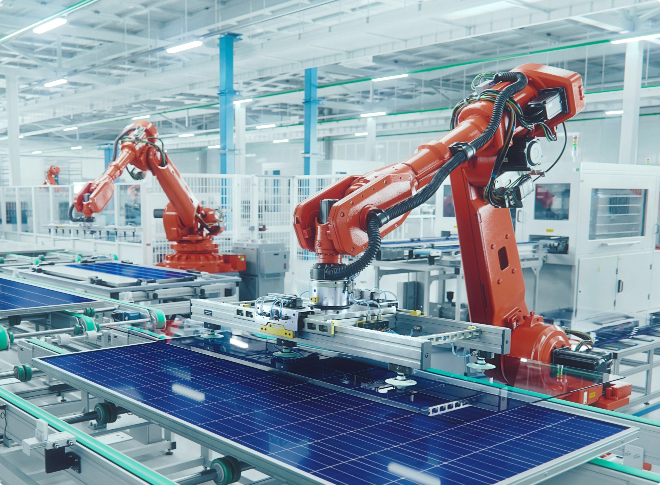

Smart Factory Consulting

The greatest differentiator of LTTS is our experience with world-class manufacturing facilities across diverse industries. We have helped companies at varying stages of their digital maturity & roadmap. The focus is not on implementing technology for technology sake but on aligning technology to your priorities, processes and workforce. LTTS has helped global conglomerates with smart factory consulting and in implementing large scale automation, material tracking and digital twin roll-outs.

Our smart factory consultants adopt a four-stage process:

- Assessment aligned to Business Priorities

- Solution Architecture

- Prioritization & Roadmap

- Continuous Feedback & Realignment

Success Stories