So far, 2017 has been a good year. Industrial output is steadily rising and seems set to exceed pre-recession levels, unemployment numbers are looking a little less grim, and inventory levels are registering a steady decline across the board. Simply put – manufacturing is making a global comeback. Geopolitical forces however are ushering in the winds of change. The outcome of the US election last year and the UK’s exit from the EU will reshape the business landscape for the consumer packaged goods (CPG), oil and gas (O&G), and chemical manufacturing sectors. In particular, the uncertainty surrounding the macroeconomic fallout of the Brexit is likely to damage consumer confidence and dampen spending. The mounting risk exposure will inevitably dissuade process industry operators from undertaking new capital expenditure (CAPEX)-intensive greenfield projects, prompting them instead to reengineer existing plants.

While product innovation is most commonly associated with R&D laboratories, it can emerge from changes made at a plant or process level. Just like rearranging operations around the customer can facilitate mass customization and improvements in throughput, strategically managing your production line could form the bedrock for your next innovation. Yet, 86 percent of corporate leaders have not exploited this opportunity. The reasons are manifold. One could be the fear that moving to a new operations model will attract significant regulatory challenges surrounding worker safety and environmental sustainability. After all, water, air, gas, electricity, and steam (WAGES) account for 10 to 40 percent of production costs, while fatalities and injuries at the workplace resulting from electrical and fire hazards contribute significantly to both lost man-hours and unplanned machine downtime. Many of the answers to these problems lie in the implementation of a flexible line that performs changeovers with regard to product types and numbers. This can entail the use of an automatic conveyance robot on the production line to improve productivity and reduce operational expenditure (OPEX). Tools like this could support a batch-of-one environment with fewer workstations, more space, and greater control.

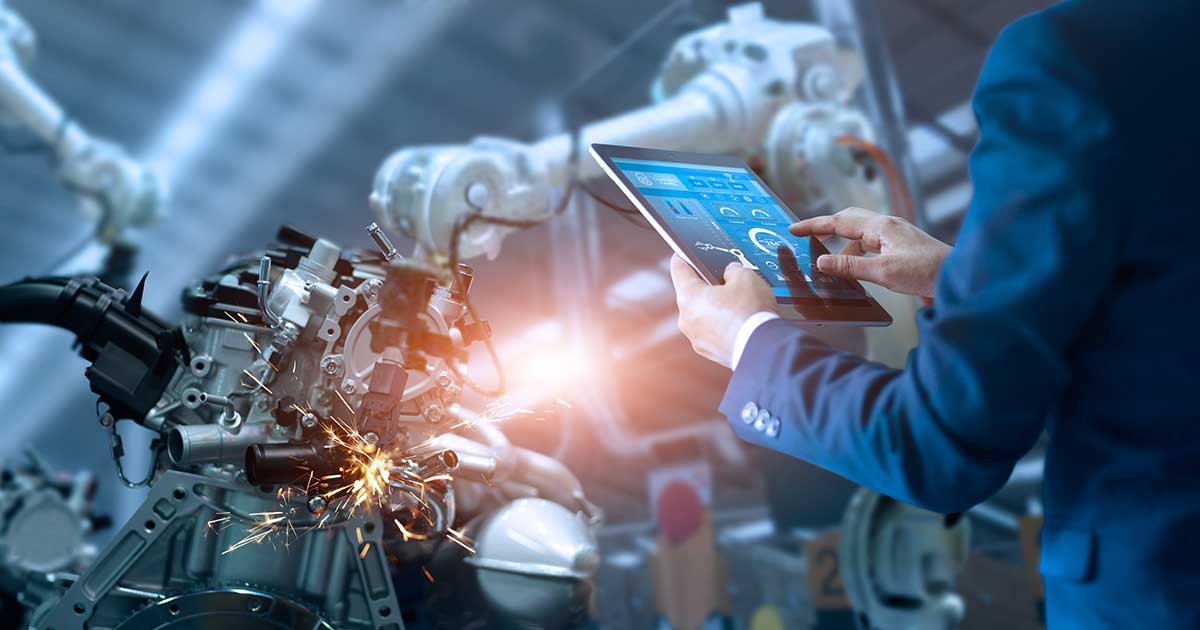

With manufacturers increasingly focusing on agility, responsiveness and personalization, plant workers need to seamlessly and efficiently collaborate at every level—from design and prototyping to sourcing and assembly. Ideally, this would mean operating as a unified ‘one plant’ ecosystem that is integrated, predictive, lean, agile, and enabled by the Industrial Internet of Things (IIoT). The IIoT will serve as the glue that holds together the transition from conventional to smart manufacturing. Smart sensors and meters will become a ubiquitous part of the plant’s architecture, allowing manufacturers to take the next step towards managing utility consumption to support efficiency and conservation goals. In fact, the same mesh of IIoT sensors that support connected manufacturing and predictive maintenance, can be leveraged to track energy performance, monitor for leaks, and flag any subpar operating situations. It also creates the scope for sending out real-time alerts to notify energy managers about waste and energy sinkholes, enabling them to take timely action before their plants deplete OPEX budgets. In the oil and gas industry, these benefits enable companies to inspect and monitor pipelines through operational intelligence. While currently only 1% of sensor data on offshore rigs informs decisions, the full-fledged use of IoT and analytics could reduce OPEX by 5% and CAPEX by 20%. For the CPG and chemical industries too, operational visibility will enable plant operators to extract the most out of every dollar spent.

Process industries are ripe for state-of-the-art disciplined engineering that covers everything from asset management to plant simulation and modularization. With a ‘one plant’ ecosystem, operational feasibility also hinges on the ability to optimize machine life and reduce unplanned downtime through prescriptive maintenance. Here is where integrated asset management (IAM) comes into play, enabling real-time condition-based monitoring and predictive analytics to drive maintenance, repair, and overhaul (MRO) activities. While a predictive maintenance (PdM) framework can only identify potential machine failure or other similar catastrophic events, it paves the way for implementing prescriptive maintenance (RxM). This factors in additional inputs like parts quality, warranty and engineering data, before initiating maintenance operations. Since it takes the human decision maker out of the equation, it improves response time and diminishes the scope for error. In a way, RxM removes dependency on manual checks and assessments, and automates the maintenance workflow. Although many process industry players acknowledge the importance of these steps, they tend to stagger such programs to minimize the impact on their CAPEX and R&D activities. Many choose to focus on their core activities and partner with engineering service providers to outsource peripheral activities. This way, plant owners continue pushing the boundaries of innovation while daily activities are taken care of by plant and process engineering specialists. Will manufacturing benefit from such a model? Share your thoughts in the comment section so that we can continue this conversation.