Digital Engineering Services

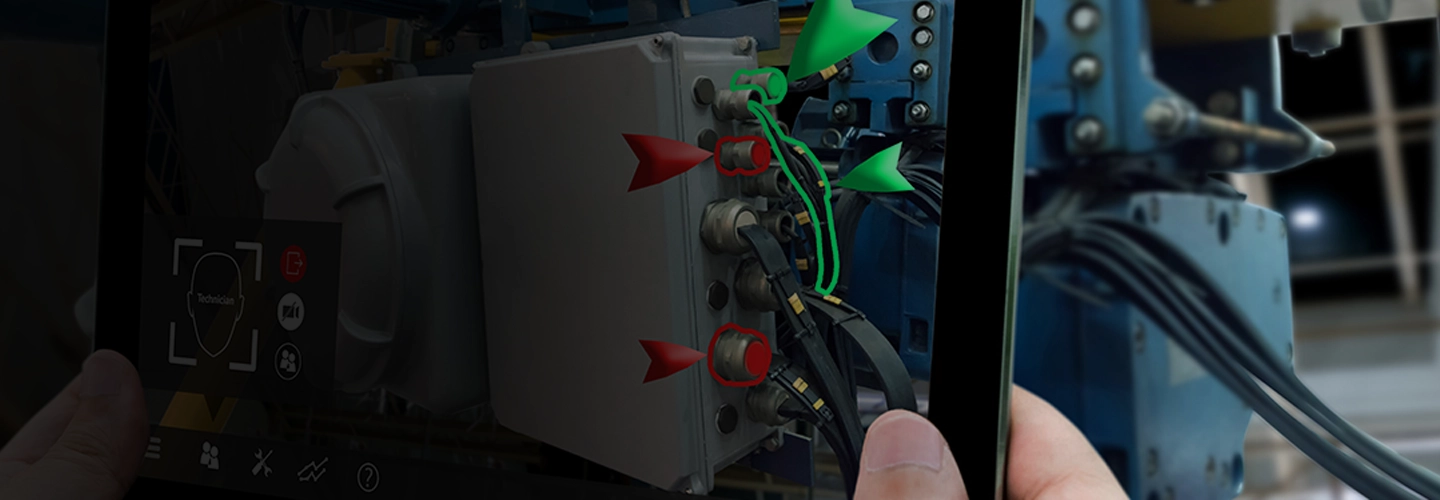

Digitalization addresses key challenges for manufacturers worldwide. Predictive maintenance helps minimize unplanned downtime by monitoring asset health, while real-time analytics enables early error detection and corrective actions.

We help plant owners and operators harness the power of digital technologies to drive efficiency, improve productivity, ensure ease of operations, streamline metrics visualization, protect against cyberattacks, enable system maintenance/sustenance, and optimize costs across the ecosystem.

LTTS Solution Offerings

- Avertle: Condition Based Predictive Maintenance of Critical Assets

- OEED: An Intelligent solution to evaluate the Overall Equipment Effectiveness and Downtime analysis of a production line

- Golden Batch: Reporting solution to analyze the parameters hampering the quality and volume of production in each time frame

- i-BEMS: Intelligent Building Experience & Energy Management System

- W.A.G.E.S & Energy Manager: Digital Energy Monitoring Solution for manufacturing plants

- ARC: A solution to Improve Plant Reliability by reducing plant downtime and improve actions towards plant uptime elements

- RAPM: Track & Trace for Asset/Material/Workers

What Makes Us Different

Library of Digital Assets – Tools & Templates, Frameworks, Platform, Solutions

Joint Investments for Building Innovative Digital Solution (As Agreed Mutually) by White Labelling LTTS IP Solutions

Consultative & ‘Design Thinking’ Led Engagement Approach

Faster Turnaround of Digital Solutions and Return on Value

Success Stories

Resources