Semiconductor Capital Equipment

With decades of experience in driving state-of-the-art innovation and deploying engineering solutions worldwide, LTTS is the preferred partner for leading global semiconductor equipment manufacturers. Our range of offerings encompass the complete semiconductor capital equipment manufacturing lifecycle – from creating fabs to wafer inspections.

LTTS Offerings

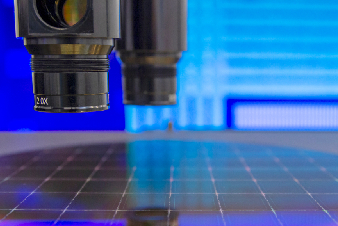

Mask Manufacturing

- Mask Template Creation Optical

- Proximity Correction

- Inspection and Metrology

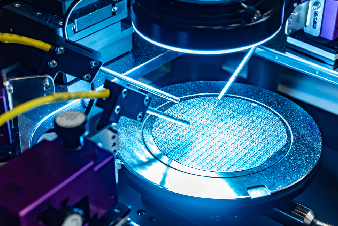

Wafer Manufacturing

- Crystal Growth

- Wafer Slicing, Grinding

- Etching, Polishing

Front End

- Cleaning

- Oxidation, Deposition Lithography

- Ion Deposition

- Inspection

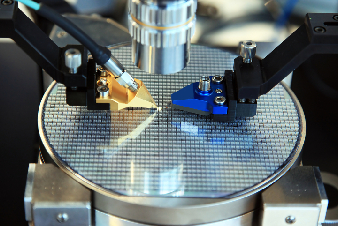

Water Testing

- Wafer Probe Test

- Multi Cell Test

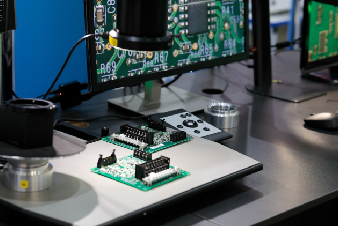

Back End

- Polish Grinding / Dicing

- Wafer Mounting, Bonding, Molding

- Inspection

Cleanroom Solutions

- Storage and Material Handling Systems

- Contamination Control

- Fluid Control

The LTTS Edge

The LTTS Advantage

LTTS empowers leading global semiconductor companies to revolutionize their business paradigms through:

- Decades worth of domain expertise across innovative solutions.

- State-of-the-art lab infrastructure for advanced research and development.

- Pioneering investments across benchmark-setting motion controllers.

- Deep knowledge of SEMI standards, coupled with expertise in industrial protocols.

- A robust global pool of precision machine design SMEs, delivering exceptional engineering precision.

- Comprehensive industrial protocol expertise across seamless system integration and operations.

Success Stories

Resources