i-BEMS

Proprietary building automation framework leveraging enterprise IoT for unifying all campus operations under one system using advanced energy analytics and fault diagnostics for enhanced facility operations

Explore

UBIQWeise 2.0ᵀᴹ

Rapid customization and deployment of proprietary, cloud-based IoT platform, UBIQWEISE 2.0 – supporting best-in-class big data and analytics, stream processing, and real-time business insights

Explore

ESM

Cloud-based utility monitoring solution for collection and visualization of data from across locations, enabling customized forecasting and load profiling within unified dashboards

Explore

Semiconductor IP

Collaboration with global technology leaders and hyperscalers across semiconductors, chip manufacturing, and original devices to enable next-gen smart solutions for cutting-edge device connectivity

Explore

EvQUAL

Proprietary, AI-enabled test automation suite for multi-platform and multi-device automation, enabling time, location, and device-agnostic remote manual and automation testing.

Explore

nBon

NB-IoT solution leveraging a 3GPP Release 14 compliant Cat NB1 reference protocol stack (L1/L2/L3) for IoT low data rate devices, providing comprehensive device management capabilities using LWM2M (DM, FOTA, SOTA)

Explore

FlyBoard®

In-house developed digital signage solution, leveraging robust analytics and machine learning features for deeper user insights and comprehensive customer experience journeys

Explore

Connected Security Framework

A robust cybersecurity solution, Connected Security Framework, combining individual components for enabling the security of connected products, services, and infrastructure across industries

Explore

Chest-rAi™

AI-based Chest X-Ray Radiology suite for symptom detection, localization and intelligence reporting, with the ability to detect ~34 of the most common lung-related abnormalities –enabling over 85% healthcare diagnosis requirements

Explore

Asset Reliability Centre

ARC, a six-pillar framework to help asset-intensive manufacturers drive optimal operations by balancing asset cost, availability, and reliability– from factory to machine component level

Explore

AnnotAI

AI-based, cloud-agnostic data annotation tool, supporting multi-sensor data labeling with high accuracy and acceleration of compute vision training for autonomous vehicles, robotics, and other applications

Explore

AiCE

A comprehensive tool, AiCE helps redefine Clinical Evaluation Report processes by performing AI-enabled systematic reviews and reporting on clinical literature and additional, relevant databases

Explore

Fusion

Fusion Suite Addressing Challenges across Urban Public Safety, Smart Cities, & Industry 4.0 Worldwide, organizations, urban planners, and governments are moving beyond the exciting capabilities and offerings of smart building and spaces. A quick evaluation of the emerging demand pattern reveals a growing shift in favor of sustainable and smart worlds, indicating the need for thinking and

Explore

Asset Health Framework

AI-enabled, real-time, cloud-native-based Asset Health Framework for gathering, analyzing, and diagnosing key asset health parameters – enabling a scalable and customizable data pipeline for rapid decisions

Explore

EDGYneer

Out-of-the-box device management solution for connecting, onboarding, monitoring, and maintaining remote assets – ensuring a unified security management ecosystem, and enabling edge data aggregation, processing, storage, and analytics

Explore

Plant Safety Management

Centre of Excellence offering consolidated safety offerings for protecting plants, personnel, processes, and equipment, and enabling a systematic approach toward the identification, evaluation, and mitigation of plant operation risks

Explore

Sensor & Gateway Solution

OEM agnostic, end-to-end Sensor to Gateway to Data Insight solution, helping transform user experiences leveraging smart IoT sensor technology for actionable, real-time insights on asset health

Explore

SafeX

Comprehensive CI/CD/CT framework for streamlining and optimizing software delivery processes, SafeX enables the set up and management of mature pipelines without prior expertise in CI/CD tools

Explore

AiKno®

AiKno® analysis framework for real-time visibility into asset health, predictive detection of anomalies , and automatic generation of service requests and machines-run self-diagnostics

Explore

Nliten

Content delivery framework integrating best-of-breed solutions, API-driven microservices, component adapters, orchestrator engines, and development accelerators for simplified workflows across the global media and entertainment ecosystem

Explore

PLxAI

Accelerating Product Development Lifecycles with AI by seamlessly integrating advanced engineering, scalable architectures, and lifecycle optimization for unmatched precision and efficiency.

Explore

LTTSiDriVe™

LTTSiDriVe™ is a semicon-agnostic SDV platform featuring GenAI-enabled automation, shift-left testing with Virtual Nodes, and integrated tools for seamless, efficient development.

Explore

TrackEi™

Ensure rail safety and efficiency globally with LTTS’ TrackEi™ - a high-speed AI-driven rail inspection system. Detect defects in real-time at speeds up to 100 kmph.

Explore

Resources

POV

Driver-In-Loop (DIL) For Testing ADAS Features

Driver-in-the-Loop (DIL) testing has become a cornerstone in the assessment of Advanced Driver Assistance Systems (ADAS) within the automotive industry.

Case Studies

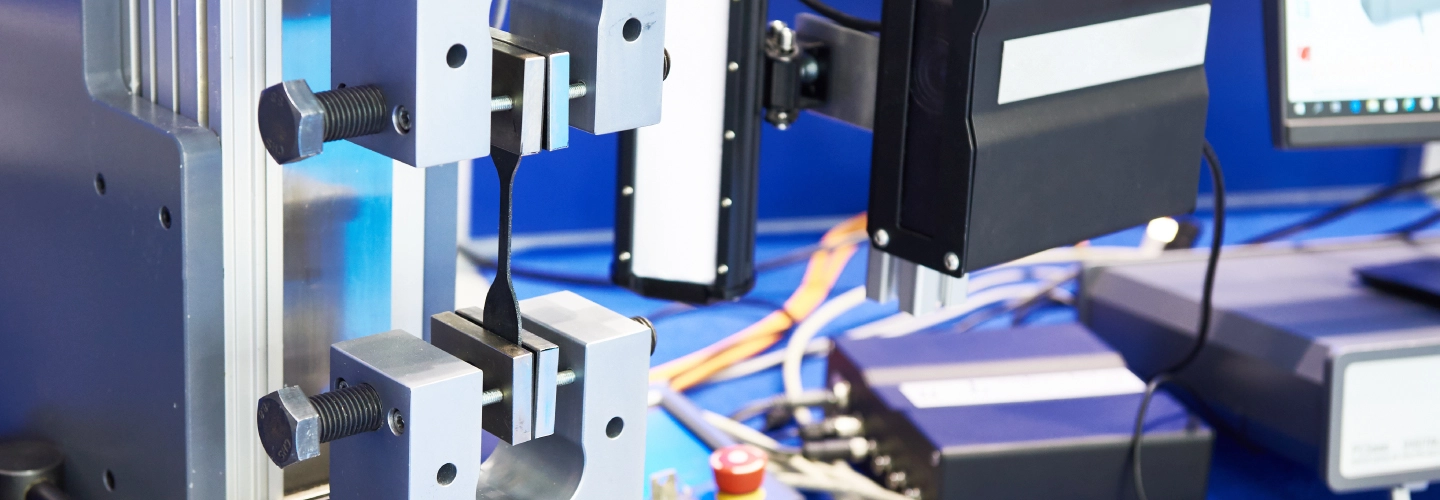

From Bottlenecks to Breakthroughs: A Tier 1 Supplier’s Journey in Material Testing Excellence

In an industry where efficiency, cost management, and compliance are critical, one leading Tier 1 supplier headquartered in Japan redefines what's possible.

Know More

Pioneering 5G Connectivity in Automotive: A Case Study on Next-gen Telematics Control Unit and Conne...

In the rapidly evolving automotive sector, our client aimed to be at the forefront of innovation by integrating next-generation 5G connectivity into their vehicles.

Know More